Kafka in the Cloud: Why it’s 10x better with Confluent | Find out more

Real-Time Predictive Maintenance

Collect and analyze real-time data generated during the manufacturing process to prevent tooling failures or re-work. Real-time visibility into the manufacturing process delivers an outsized impact on production volume and quality.

Move from a Reactive Operating Model to a Proactive One

Reacting to parts that are out of spec is not enough. Confluent allows you to leverage streaming data to minimize equipment downtime by capturing and analyzing real-time data on the line.

Subsequent insights enable predictive maintenance, which limits scrap and saves costs. Maintenance windows can be streamlined and timed to coincide with other complementary activities which increases efficiency. Additionally, early maintenance on expensive manufacturing tooling significantly extends equipment lifespan.

Enable instant reactions to engine quality.

Unlock real-time insights into tooling quality.

Provide visibility into engine tooling to indicate when maintenance will be required.

Build with Confluent

This use case leverages the following building blocks in Confluent Cloud:

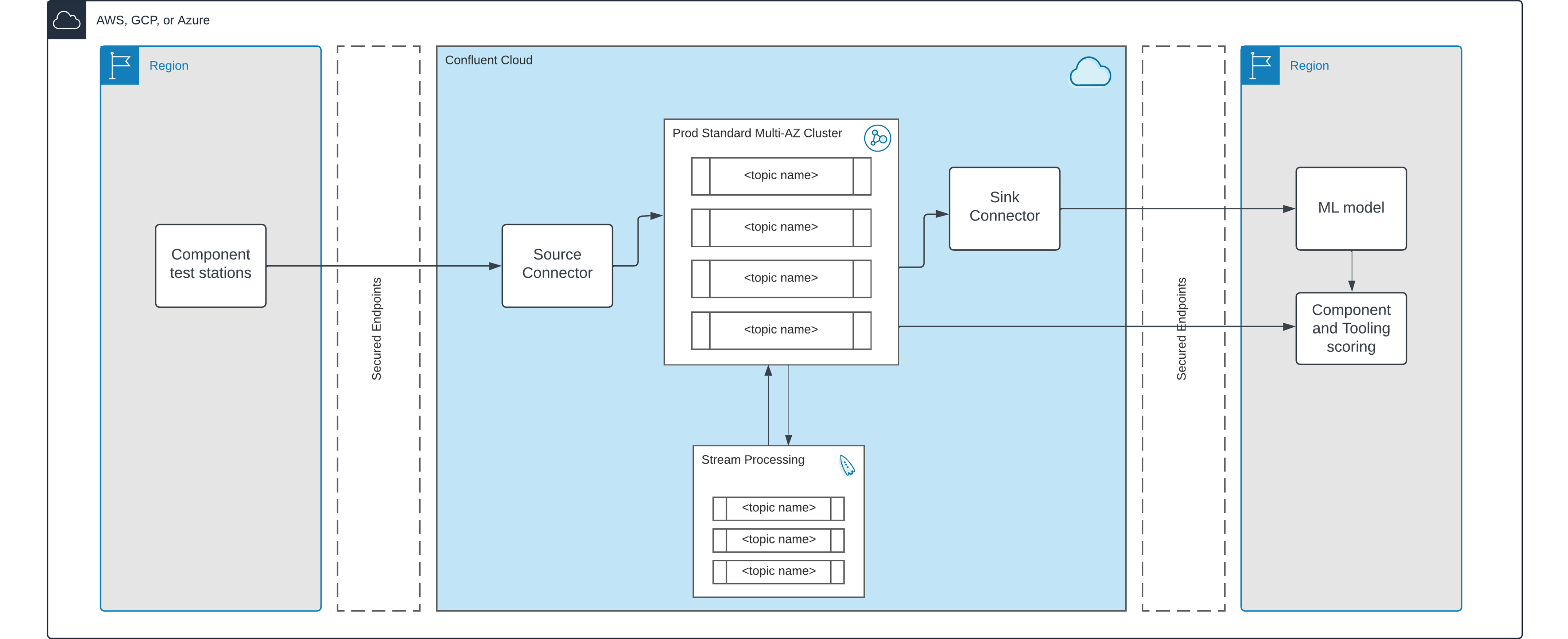

Reference Architecture

This reference architecture shows how Confluent Cloud can power quality control as part of the manufacturing process.

All OT data emitted as part of the manufacturing process is written to topics in Confluent Cloud in real time. Since data volume and size aren’t a limiting factor, granular time-series data can be streamed from historians (or directly from MQTT).

All data consumed is made available to train a machine learning model in real time.

High-volume scoring is completed at line speed against the latest published version of the ML model. Based on scoring and the defined quality specs, operator personnel at the plant can quickly react to any system-generated alerts.