[Virtuelles Event] GenAI Streamposium: Lerne, Echtzeit-GenAI-Apps zu entwickeln und zu skalieren | Jetzt registrieren

What is a DCS?

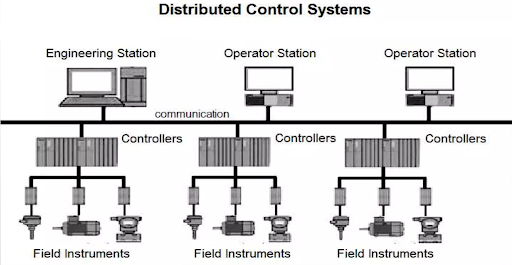

A Distributed Control System (DCS) is a control system used in industrial processes to manage and automate complex operations. Unlike traditional centralized control systems, a DCS uses decentralized control elements distributed throughout the system. Each component can communicate with others, providing a comprehensive framework for monitoring and controlling processes in real time.

Why Use a DCS?

The primary reasons for using a DCS include improved reliability, flexibility, and scalability. DCS systems allow for real-time monitoring, which is crucial for maintaining process efficiency and safety. By distributing control across various nodes, the system minimizes the risk of a single point of failure, thus enhancing operational reliability.

Confluent Cloud's capabilities enhance DCS systems by enabling seamless integration and real-time data streaming. This means that data from various nodes in the DCS can be ingested, processed, and analyzed in real time, improving decision-making and operational efficiency.

Components and Architecture

A DCS typically consists of several key components:

-

Control Nodes: These are the devices that execute control functions.

-

Human-Machine Interface (HMI): This allows operators to interact with the system and visualize data.

-

Data Communication Network: Facilitates data transfer between control nodes and the HMI.

-

Field Instruments: These sensors and actuators collect data from the physical environment and execute control actions.

DCS vs. SCADA and PLC Systems

While DCS, SCADA (Supervisory Control and Data Acquisition), and PLC (Programmable Logic Controller) systems all serve the purpose of controlling industrial processes, they have distinct differences:

DCS

Primarily used for complex processes where continuous control and monitoring are required.

SCADA

Generally used for monitoring and controlling large-scale systems, such as water treatment facilities and power grids. It focuses more on supervisory control.

PLC

Best for discrete control processes, such as assembly lines, where simple on/off control is sufficient.

Confluent Cloud can bridge the gaps between these systems, providing a unified data architecture that streamlines operations. By integrating data from DCS, SCADA, and PLC systems, businesses can gain a comprehensive view of their processes.

Core Functions and Benefits of a DCS

The core functions of a DCS include:

Real-Time Monitoring

Constant observation of processes to ensure optimal performance.

Data Logging

ecording historical data for compliance and analysis.

Automated Control

Enabling automatic adjustments based on real-time data inputs.

Benefits of a DCS : Unlocking Operational Excellence

A Distributed Control System (DCS) offers a range of benefits that significantly enhance operational efficiency in industrial environments.

Improved Real-Time Monitoring

By continuously collecting and analyzing data from various processes, a DCS enables organizations to maintain optimal performance levels and quickly identify potential issues. This proactive approach minimizes downtime, reduces maintenance costs, and enhances overall productivity. Streamlined processes lead to reduced downtime and increased productivity, making a DCS an invaluable asset for any industrial operation.

Automated Control

Through advanced algorithms and data analytics, a DCS can automatically adjust processes based on real-time inputs, improving consistency and quality in production. Continuous monitoring helps in the early detection of potential hazards, thereby enhancing safety across operations. By leveraging Confluent Cloud, organizations can further enhance this automated control by integrating real-time data streams, enabling even more sophisticated adjustments and decision-making capabilities.

Better Data-Driven Decision Making

By centralizing and analyzing operational data, organizations gain insights that were previously difficult to access. This capability allows for more informed strategic planning and resource allocation. With access to real-time data, businesses can make proactive adjustments based on historical and current information. Confluent Cloud enhances these benefits by providing advanced analytics and machine learning capabilities, transforming DCS data into actionable intelligence. Ultimately, the benefits of a DCS, combined with advanced cloud solutions, empower organizations to achieve operational excellence and maintain a competitive edge in a rapidly evolving market.

DCS and Data Integration

Data integration is essential for Distributed Control Systems (DCS), as it enables the seamless flow of information from diverse sources, enhancing operational efficiency. In industrial settings, a DCS collects vast amounts of data from sensors, controllers, and field instruments. However, without effective integration with critical business systems such as ERP (Enterprise Resource Planning), CRM (Customer Relationship Management), and supply chain management, this valuable data can become siloed. This limits its potential for actionable insights and informed decision-making. By leveraging Confluent Cloud, organizations can effortlessly connect their DCS data with these external systems, providing a comprehensive view of operations and facilitating data-driven strategies that enhance productivity and profitability.

Confluent Cloud offers robust real-time data streaming capabilities that significantly enhance the integration of DCS with other applications. This powerful platform allows organizations to process and analyze data as it flows from various DCS components, enabling instant insights and timely responses. For instance, by integrating production data with inventory management systems, businesses can optimize their supply chains, reduce waste, and improve overall operational efficiency.

Moreover, the scalability and flexibility of Confluent Cloud make it an ideal solution for modernizing DCS data integration efforts. As industrial environments evolve and expand, the demand for seamless data flow becomes critical. Confluent’s capabilities allow organizations to adapt their integration strategies effortlessly, accommodating new data sources and evolving business requirements without significant disruption. By integrating DCS with Confluent Cloud, organizations position themselves for future success and operational excellence.

Advanced Applications of DCS in Industry

DCS systems are increasingly being used in advanced applications such as:

Predictive Maintenance

DCS enables organizations to continuously monitor equipment performance and analyze data trends to identify potential failures before they occur. This proactive approach allows for timely maintenance scheduling, reducing unexpected downtime and optimizing maintenance costs.

Process Optimization

In industries such as pharmaceuticals and food processing, DCS automates complex processes by dynamically adjusting parameters based on real-time data from sensors. This leads to improved product quality, reduced waste, and lower energy consumption.

Real-Time Supply Chain Management

DCS facilitates the monitoring of inventory levels and production schedules, allowing organizations to respond quickly to changes in demand. By integrating supply chain data with DCS, businesses can achieve a more agile and efficient operation.

Energy Management

DCS can monitor energy consumption across processes and identify inefficiencies in real time. By optimizing energy use, organizations can significantly reduce costs and enhance sustainability efforts.

Quality Control

Continuous data monitoring allows DCS to ensure that production processes consistently meet quality standards. This capability enables immediate corrective actions to be taken, minimizing the risk of defective products reaching the market.

Enhanced Safety Monitoring

DCS can integrate safety systems to continuously monitor critical parameters, helping to detect hazardous conditions early. This real-time monitoring supports rapid response actions, significantly improving workplace safety.

Batch Process Management

In industries like chemicals and food, DCS manages batch processes by controlling the timing and order of operations. This precision ensures consistent product quality and compliance with regulatory standards.

Remote Monitoring and Control

DCS enables operators to monitor and control processes from remote locations, enhancing flexibility and responsiveness. This capability is especially valuable in geographically dispersed operations, allowing for centralized management.

Data Visualization and Reporting

Advanced DCS systems provide intuitive dashboards and reporting tools that visualize key performance indicators (KPIs). These insights empower decision-makers to quickly assess operations and make informed strategic decisions.

Integration with IoT Devices

By connecting DCS with Industrial Internet of Things (IoT) devices, organizations can gather and analyze data from a wide range of sources. This integration enhances operational visibility and facilitates smarter decision-making across the organization.

DCS in the Era of Industry 4.0: Driving Smart Manufacturing

The advent of Industry 4.0 represents a significant transformation in industrial operations, emphasizing automation, data exchange, and the Internet of Things (IoT). In this new landscape, Distributed Control Systems (DCS) play a pivotal role by serving as the backbone for smart manufacturing processes. A DCS enables real-time monitoring and control of production systems, allowing organizations to optimize operations while swiftly responding to changing market demands. By integrating advanced technologies, a DCS supports the seamless flow of data across all levels of an organization, enhancing collaboration and informed decision-making.

One of the key advantages of DCS within the context of Industry 4.0 is its capability to leverage big data analytics. As manufacturing environments become increasingly connected, the volume of data generated grows exponentially. A DCS can capture this data from various sources, enabling organizations to analyze trends, predict equipment failures, and identify areas for process improvement. By integrating with Confluent Cloud, companies can utilize powerful data streaming capabilities to ensure that insights are derived in real time. This real-time analysis enables informed decisions that enhance operational efficiency and productivity, essential for maintaining a competitive edge in the modern marketplace.

DCS Security and Compliance

In today’s industrial landscape, the security of Distributed Control Systems (DCS) is paramount, especially as cyber threats become increasingly sophisticated. DCS environments often manage critical infrastructure and sensitive data, making them attractive targets for malicious actors. Implementing robust security measures is essential to protect these systems from potential breaches. This is where Confluent Cloud comes into play, offering advanced security features that enhance the protection of DCS environments, including data encryption, access controls, and real-time monitoring of data streams.

Compliance with industry regulations is another crucial aspect of DCS security. Many sectors, such as pharmaceuticals and energy, are subject to stringent regulatory requirements that mandate secure data handling and reporting practices. A DCS must not only safeguard operational data but also ensure that it meets these compliance standards. By leveraging Confluent Cloud, organizations can streamline their compliance efforts through automated data governance and comprehensive audit trails. This capability simplifies the process of tracking data access and modifications, making it easier to demonstrate compliance during audits.

Furthermore, the integration of DCS with Confluent Cloud enables organizations to enhance their security posture through real-time analytics and threat detection. By continuously monitoring data flows and user activity, organizations can identify anomalies that may indicate a security breach. This proactive approach allows for immediate response actions to mitigate potential risks before they escalate. With the ability to correlate DCS data with broader enterprise security measures, businesses can create a holistic security framework that not only protects their systems but also fosters confidence among stakeholders regarding the integrity and reliability of their operations. In an era where security and compliance are critical, the synergy between DCS and Confluent Cloud empowers organizations to operate securely and efficiently.

DCS Modernization

Modernizing a DCS is essential for leveraging new technologies and ensuring continued operational efficiency. This may involve upgrading hardware, incorporating advanced software, or migrating to cloud-based systems.

Confluent facilitates DCS modernization by providing a scalable platform that can integrate legacy systems with modern cloud solutions. This enables organizations to evolve their DCS capabilities without losing valuable historical data.

Benefits of DCS with Confluent’s Real-Time Data Streaming

Integrating DCS with Confluent’s real-time data streaming capabilities offers several benefits:

Enhanced Operational Efficiency

- Integrating DCS with Confluent enables real-time monitoring and control of complex processes.

- Instant insights into system performance allow for quick responses to anomalies and trends.

- Reduces downtime and improves overall decision-making across operations.

Improved Data Accessibility

- Confluent Cloud centralizes data from multiple sources, including sensors and external applications.

- Provides comprehensive visibility into operations, facilitating effective performance analysis.

- Enables informed decision-making based on up-to-date information, driving productivity.

Advanced Analytics and Predictive Maintenance

- Real-time data streaming allows for the implementation of predictive analytics.

- Identifies potential failures before they occur, promoting proactive maintenance strategies.

- Unlocks actionable insights from operational data, leading to enhanced process efficiencies and reduced costs.

Streamlined Resource Allocation

- Access to real-time insights enables better strategic planning and resource management.

- Organizations can optimize workflows and allocate resources effectively based on current data.

Competitive Edge

- Combining DCS with Confluent positions organizations to innovate and adapt in a data-driven landscape.

- Facilitates faster decision-making, ensuring organizations remain agile and responsive to market changes.

Conclusion

Distributed Control Systems are vital for managing complex industrial processes. Their integration with Confluent Cloud brings significant advantages, including real-time data streaming, advanced analytics, and enhanced security. As industries move towards automation and Industry 4.0, the synergy between DCS and Confluent will become increasingly essential for driving operational excellence and innovation.

By leveraging the capabilities of Confluent, organizations can maximize the benefits of their DCS investments, ensuring they remain competitive in a rapidly evolving industrial landscape.